ADI (Analog Devices Inc.)

Analog Devices Inc. (ADI) is a multinational semiconductor company specializing in the design and manufacturing of analog, mixed-signal, and digital signal processing (DSP) integrated circuits. The company was founded in 1965 and is headquartered in Norwood, Massachusetts, USA.

Analog Devices produces a wide range of products that are used in various applications, including automotive, communications, industrial, healthcare, and consumer electronics. Some of their key product categories include:

-

Analog Products: This includes a diverse range of analog integrated circuits such as amplifiers, data converters, voltage regulators, and more.

-

Mixed-Signal Products: These are integrated circuits that combine both analog and digital functions. Examples include analog-to-digital converters (ADCs), digital-to-analog converters (DACs), and mixed-signal processors.

-

Digital Signal Processing (DSP) Products: ADI is a leader in DSP technology, providing processors and software for applications like audio processing, communications, and control systems.

-

Microcontroller and Processors: Analog Devices offers a variety of microcontrollers and processors for applications that require embedded computing capabilities.

-

MEMS (Micro-Electro-Mechanical Systems): ADI is involved in the development of MEMS technology, including accelerometers, gyroscopes, and inertial measurement units (IMUs).

The company serves a broad customer base, including original equipment manufacturers (OEMs), distributors, and electronic manufacturing service providers. Analog Devices plays a crucial role in enabling technology advancements in various industries by providing high-performance and innovative semiconductor solutions.

Product Lines

-

Semiconductors

-

Power

-

Drivers And Interfaces

-

Sensors

-

Transistors

-

Signal Circuits

Featured Products

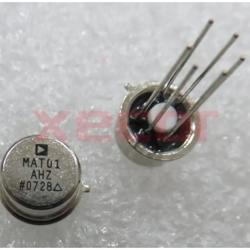

MAT01AHZ

Trans GP BJT NPN 45V 0.025A 1800mW 6-Pin TO-78 Tube

LT1776CN8

Switching Voltage Regulators LT1776 - Wide Input Range, High Efficiency, Step-Down Switching Regulator

LT1249CN8

PFC IC Average Current 100kHz 8-PDIP

LT1248IN

Power Factor Controller, Current-mode, 1.5A, 300kHz Switching Freq-Max, BIPolar, PDIP16

LT1370CR

Conv DC-DC 2.4V to 30V Non-Inv/Inv/Step Up/Step Down Single-Out 1.245V to 35V 6A 8-Pin(7+Tab) DDPAK

LT317AT

LDO Regulator Pos 1.5A 3-Pin(3+Tab) TO-220

LT323AT#PBF

LDO Voltage Regulators 5 Volt, 3 Amp Voltage Regulator

LT1529CQ

LDO Regulator Pos 3.8V to 14V 3A 6-Pin(5+Tab) DDPAK