Industrial Wireless Connectivity Technology

Wireless Communication in Industrial Applications

Wireless communication has been used in industrial applications for many years, initially for basic control of cranes and other mobile equipment. With the adoption of more standardized wireless connectivity technologies in recent decades, control has expanded to a wider range of terminal devices.

In industrial applications, no single wireless technology can meet all requirements. Low bandwidth and low-power technologies are more suitable for intermittently connected instrumentation devices. Conversely, for unmanned Automated Guided Vehicles (AGVs) deployed in busy factory environments requiring continuous communication between multiple sensors, higher bandwidth options should be chosen.

ADI offers a variety of wireless communication technologies that eliminate the need for wired networks, allowing sensors in remote and hard-to-reach hazardous areas to be connected. ADI provides highly advanced wireless subsystems and complete signal chain solutions designed to reduce design complexity and accelerate deployment. These solutions include SmartMesh®, 5G, Low-Energy Bluetooth® (BLE), and 60 GHz low-latency wireless data connectivity. If you want to build reliable wireless connections, you can choose ADI's validated technologies to get started immediately.

SmartMesh: Wireless Communication for Demanding Industrial IoT Environments

ADI's SmartMesh transceivers are low-power, highly reliable, standards-based wireless sensor network (WSN) solutions that extend battery life. SmartMesh networks can provide data reliability greater than 99.999% in harsh RF environments. Industrial Internet of Things (IIoT) solution providers choose this network to deliver critical low-bandwidth sensor measurement data in remote and hazardous locations. SmartMesh products require no network stack development and offer encryption, authentication, and message integrity checks.

5G: Highly Reliable, Low-Latency Wireless Connectivity

Utilizing Ultra-Reliable Low Latency Communications (URLLC), 5G technology expands the potential of wireless connectivity in manufacturing and other industrial applications. Now, connectivity can be added almost anywhere, even in challenging RF environments, to increase machine data capture, improve workplace flexibility, and eliminate cumbersome cable installations. ADI is a market leader in 5G radio technology and has a wide partner ecosystem for deploying dedicated 5G networks in both greenfield sites and existing factories.

60 GHz Low-Latency Wireless Data Link

Bluetooth, WLAN, and 5G are effective means of data transmission and reception. However, all packet-based wireless connectivity standards suffer from one common issue: latency in the link. Therefore, communication is not real-time. This affects the response time of devices from command creation to receiving and executing commands. Industrial automation relies on real-time protocols (e.g., EtherCAT) that require minimal latency during communication, so wireless links must provide latency-free connections.

To address this issue, packet-based transmission protocols need to be replaced with bitstream transmission, which eliminates latency. This technology enables true wireless data links for machine interconnection, surpassing the speed of even the fastest 5G connections by several hundred times.

Starting with 60 GHz Wireless Data Interconnect

ADI's ADMV9611 and ADMV9621 60 GHz solutions offer performance comparable to wired connections. These PCB subsystems create a complete millimeter-wave (mmWave) wireless link, providing full-duplex operation. By using this technology, ADI can provide real-time, highly reliable connections for industrial automation applications.

Key Advantages of ADI's 60 GHz Technology

Ultra-Low Latency

Wireless networks are known for their inherent latency. Wi-Fi introduces latency in the order of 20 ms to Ethernet transmission, while 5G aims for 1 ms. The latency of a 60 GHz link is within 2 µs, several times faster than 5G.

Protocol-Agnostic

With ADI's 60 GHz bit input/bit output solution, existing systems or devices using commonly used wired protocols can be seamlessly integrated to adapt to the system.

Tolerance for Alignment Deviation

To accommodate various assembly and operating environments, ADI's 60 GHz link technology does not suffer performance loss when the wireless connectors are not perfectly aligned. Allowing for a certain degree of alignment deviation, this technology can be used in rotating equipment without affecting link performance, serving as a replacement for more traditional wired connection systems.

Reliable and Durable in Dusty Environments

60 GHz links are not affected by dust and debris between connectors. This means that 60 GHz solutions can be used in harsh environments without compromising performance.

Non-Contact Slip Ring Replacement Applications

60 GHz wireless link technology is ideal for replacing existing slip ring technology. Slip rings are typically used in rotating joints to transmit data within rotating assemblies. Previously, brushes were used, but they would touch the rotor and break during operation, requiring maintenance and replacement. Depending on the assembly used, this could result in high costs, especially when large assemblies needed repair or replacement. Additionally, routine maintenance is required to verify the working condition of the assembly, which can be tedious and costly. Using ADI's 60 GHz link technology eliminates physical contact, allowing for the use of wireless connections in rotating joints, reducing the need for routine maintenance, repairs, or replacements.

BLE: Ultra-Low-Power, Advanced Endpoint Secure Wireless Connectivity Technology

BLE remains a cornerstone for building a smarter, more connected world. Millions of wireless devices will be deployed in smart buildings, smart homes, and smart factories, presenting unique challenges in protecting and powering these endpoint devices. ADI's Darwin series microcontrollers and low-power integrated BLE 5.2 radios are designed specifically to address these unique challenges.

Radio

In Bluetooth direction-finding applications, Bluetooth 5.2 SoCs support Angle of Arrival (AoA) and Angle of Departure (AoD) features. They also support LE Audio, Long Range, and High Throughput 2 Mbps features. Additionally, they support mesh protocols such as Bluetooth Mesh and Zigbee.

Low Power

Active mode power consumption as low as 27.3 µA/MHz helps extend battery life. On-board SIMO provides dynamic voltage regulation to minimize power consumption of the active core as much as possible. Fast wake-up times in various operating modes optimize power consumption for any application.

Security and Reliability

Built on advanced hardware security technologies accumulated over 30 years, including AES, ECDSA, SHA-2/3, and PUF.

All embedded memories include error correction codes (ECC) to enhance reliability.

Size

Various package options, with the smallest being 10.2 mm².

More Application-Related Electronic Components

MC79M05CDTRKG

Linear regulators with negative feedback designed to provide a constant 5V output at a maximum current of 500mA

KSZ8895MQXIA

High-speed networking switch

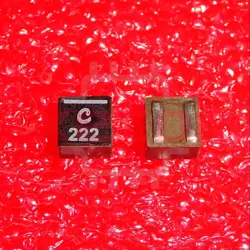

XGL4030-222MEC

2.2uH ±20% 7A 1616 Power Inductors ROHS

0900LP15B0063E

Ceramic Filters Low Pass 900MHz 0.9dB 50Ohm SMD 8Pin T/R

ZXMN10B08E6TA

ZXMN10B08E6TA is a N Channel MOSFET, featuring a voltage rating of 100V and a maximum current of 1.6A, with a low on-resistance of 230mΩ at 10V

ZXMN6A07FTA

Small Signal Field-Effect Transistor

MLX90614ESF-DCI-000-TU

Digital Temperature Sensor MLX90614ESF-DCI-000-TU, Operating Range: -40°C to 85°C, TO39 Enclosure

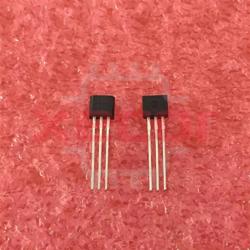

ZVN2106A

channel MOSFET with a voltage rating of 60V, current rating of 0.45A, and power dissipation of 0.7W, packaged in TO92

READ ALSO

-

Industrial Wireless Connectivity Technology Date: 08/10/2023

Wireless communication has been used in industrial applications for many years, initially for basic control of cranes and other mobile equipment. With the adoption of more standardized wireless connectivity technologies in recent decades, control has expanded to a wider range of terminal devices.

-

Industrial Wired Connectivity Technology Date: 08/10/2023

Today, wired connectivity technology remains the primary technology adopted in the industrial sector. Existing factory networks widely utilize legacy serial interfaces to ensure uninterrupted high-performance connections.

-

Vibration Detection for Condition Monitoring Date: 08/10/2023

As manufacturers seek to improve throughput and asset utilization by reducing maintenance costs and asset downtime, real-time continuous condition monitoring and predictive maintenance solutions become increasingly important. Given that the cost of unplanned downtime can account for nearly one-fourth of total manufacturing costs, adopting predictive maintenance solutions has the potential to significantly save costs and boost productivity.