MES System Collects PLC Data via OPC Intelligent Gateway

OPC is a common communication protocol in the industrial control field, used in devices such as PLCs, DCS, SCADA, and more. It enables interconnection and communication between industrial automation devices and can be integrated with other factory systems to enhance efficiency. Through the use of the Wu Tong Bolian OPC intelligent gateway, MES (Manufacturing Execution System) can obtain real-time PLC data, enabling functions such as remote monitoring, remote control, and equipment management, thus assisting enterprises in creating a digital factory and information-based management.

The entire system architecture can be divided into processes such as device networking, data acquisition, data processing, and command issuance. First, the OPC intelligent gateway collects data from control systems like PLCs, DCS, SCADA, and standardizes the data. MES then receives production data from the PLC, such as equipment operating status and process parameters. Next, MES processes the collected data through statistics, display, and analysis. It formulates rational production plans for the factory or specifies certain operations for the equipment. Finally, MES optimizes task instructions and sends them to the equipment for remote control. The PLC carries out the control operations on the equipment.

Gateway Features

-

Powerful Protocol Parsing Capability: The industrial intelligent gateway can simultaneously support various brands and models of PLCs, including Siemens, Schneider, Omron, Mitsubishi, Allen-Bradley (AB), Delta, and Huichuan.

-

Stable and Reliable Data Acquisition: Data can be collected and transmitted using both wired and wireless methods. The gateway supports edge computing to reduce transmission pressure and ensure data integrity.

-

Flexible Cloud Adaptation: It can simultaneously connect to different types of cloud platforms and software, including custom-developed cloud platforms, Wu Tong Bolianequipment maintenance management platform,Wu Tong Bolian configuration cloud platform, third-party cloud platforms, and more.

-

Exceptional Environmental Adaptability: Designed for industrial use, it can withstand high temperatures, low temperatures, network interruptions, and support functions like network reconnection and data resumption. It is suitable for various complex industrial environments.

-

Convenient Remote Operations and Maintenance: It allows remote configuration, debugging, diagnostics, and program updates for on-site equipment. It can also be used for remote configuration, monitoring, diagnostics, and program updates for gateways distributed worldwide.

Conclusion

Through the OPC intelligent gateway, establishing a close linkage between the MES system and the production process can enhance production efficiency, ensure production safety, and maintain product quality. This not only brings direct economic benefits but also provides new ideas and methods for innovation in industrial technology.

More Application-Related Electronic Components

MT41K512M8RH-125:E

DRAM Chip DDR3L SDRAM 4Gbit 512Mx8 1.35V 78-Pin FBGA

XGL4030-222MEC

2.2uH ±20% 7A 1616 Power Inductors ROHS

0900LP15B0063E

Ceramic Filters Low Pass 900MHz 0.9dB 50Ohm SMD 8Pin T/R

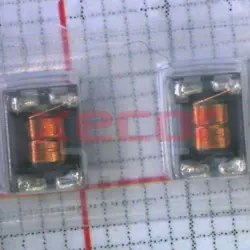

DLW43MH201XK2L

Common Mode Chokes Dual 200uH 100kHz 0.11A 4.5Ohm DCR SMD T/R Automotive AEC-Q200

Z0805C420APWST

Ferrite Beads Chip 42Ohm 25% 100MHz 4A 0.008Ohm DCR 0805 T/R

302-S101

Conn Shrouded Header (4 Sides) HDR 10 POS 2.54mm Solder ST Thru-Hole

PI3USB102GZLEX

High performance USB switch for device connectivity

SBH21-NBPN-D07-ST-BK

2 Gold 2mm -40℃~+105℃ Brass Straight Plugin Wire To Board / Wire To Wire Connector ROHS

READ ALSO

-

Rapidly Establishing a Local LoRaWAN Network Using LoRaWAN Gateways Date: 26/09/2023

LoRa modulation is a low-power, wide-area network communication technology, based on spread spectrum technology, developed by Semtech. LoRaWAN is a set of communication protocols and system architecture designed for long-range communication networks using LoRa technology. It functions as the Media Access Control (MAC) layer protocol.

-

Comprehensive Explanation of the Modbus Communication Protocol Date: 26/09/2023

The Modbus protocol is a universal language used in electronic controllers, facilitating communication between controllers, networking via Ethernet, and interaction with other devices. It has become a widely adopted industrial standard, enabling control devices from different manufacturers to connect into industrial networks for centralized monitoring.

-

MES System Collects PLC Data via OPC Intelligent Gateway Date: 25/09/2023

OPC is a common communication protocol in the industrial control field, used in devices such as PLCs, DCS, SCADA, and more. It enables interconnection and communication between industrial automation devices and can be integrated with other factory systems to enhance efficiency. Through the use of the物通博联 (Wu Tong Bolian) OPC intelligent gateway, MES (Manufacturing Execution System) can obtain real-time PLC data, enabling functions such as remote monitoring, remote control, and equipment management, thus assisting enterprises in creating a digital factory and information-based management.