How IoT solutions can help OEMs reduce costs in the aerospace industry

The potential of the Internet of Things in the aviation industry is endless. By effectively leveraging IoT, the aviation industry can focus on improving passenger safety, cost reduction, system maintenance, efficiency, safety, and customer experience.

The Internet of Things (IoT) has entered aircraft cabins, helping original equipment manufacturers (OEMs) reduce aircraft costs through smart aerospace industry solutions. Aircraft cabin electronics include the vast array of interconnected and electrically powered devices and subsystems that monitor and control the cabin. These include cabin lights, passenger service units, curtains, smoke detection, fire suppression systems, air conditioning, overhead cabin audio, water systems, waste systems, cabin crew panels, and support for in-flight entertainment systems. Airlines and OEMs are looking to manage the cost of cabin electronics as these subsystems form a significant portion of the total aircraft cost. To achieve this, OEMs are developing IoT solutions to evolve next-generation aircraft cabins at lower costs.

Why IoT-enabled aircraft cabins are a priority?

A large number of sensors and control switches are installed in the aircraft cabin system. Most of these cabin subsystems have wired components, posing serious aircraft system design and maintenance issues. The main disadvantages are as follows:

Wired connections increase cabling complexity and seriously impact the design, installation, and commissioning of these systems.

The large number of wires makes maintenance of these aircraft systems difficult

Wires also contribute significantly to aircraft weight, thereby reducing fuel efficiency

Wiring also takes up space on the aircraft, narrowing the limited space of the aircraft.

Using wireless sensors and control mechanisms in an IoT world, OEMs can significantly reduce aircraft engineering, installation, and maintenance costs.

How to design an aircraft cabin subsystem that supports the Internet of Things?

The aircraft cabin subsystem that supports the Internet of Things consists of three parts: terminal equipment, mesh communication network, and information center. Thread technology based on 6LoWPAN, which in turn uses the IEEE 802.15.4 wireless protocol to communicate with the mesh, consists of several end device nodes and a border router, forming the basic monitoring and control area, located at the bottom of the system. Border routers can also act as gateways.

Terminal equipment can be configured with single or multiple different precision sensors and actuators for subsystem operations. Terminal device nodes are deployed in the monitoring area.

In a self-organizing manner, terminal device nodes form a wireless sensor network and collaboratively sense and collect network coverage areas. After the primary processing of the detected information, the monitoring information is relayed through the thread network to the border router/gateway. The gateway node then sends this information to the central monitor and controller via the aircraft's Ethernet network. Finally, the controller comprehensively manages and configures the terminal device network based on the monitoring data of the subsystem.

Each end device node can also be connected to some control mechanisms, such as lights and LED indicators. The controller can perform any control operations on the device, which are first sent from the controller to the gateway via the aircraft's Ethernet network. The gateway then sends control commands to the end device over the Thread mesh network. The terminal device receives the command and takes appropriate action, such as turning a light on/off.

Any traditional aircraft subsystem, such as a cabin management system, consists of sensors and actuators connected to a central controller using wires. The flight attendant panel is connected to the cabin management controller via Ethernet using the aircraft's network system. To upgrade this system to wireless, we can integrate low-power wireless MCUs with sensors and actuators to communicate with IoT gateways through RF protocols such as Thread, BLE, or Zigbee. The cabin management system controller can communicate with the IoT gateway over Ethernet using the MQTT protocol. An MQTT broker can be deployed in the cabin management system controller to enable publish and subscribe mechanisms through the gateway and flight attendant panels. When the sensor sends status, it can be displayed on the flight attendant panel and any control from the flight attendant panel can be relayed to the actuators.

How can IoT-enabled subsystems help OEMs reduce costs?

One of the leading OEMs providing advanced aerospace solutions approached VOLANSYS to develop an aircraft Wireless Cabin Control System (WCCS) to reduce overall weight and simplify various cabin control components such as lights, overhead bins, and passenger services Unit (PSU)), ultimately reducing installation labor costs. VOLANSYS is a leading IoT solution provider for the aviation industry, helping to solve the challenges faced by aircraft manufacturers by providing intelligent aerospace industry solutions (including cabin management systems, in-flight entertainment systems, aircraft structural health monitoring systems, etc.).

More Application-Related Electronic Components

MC79M05CDTRKG

Linear regulators with negative feedback designed to provide a constant 5V output at a maximum current of 500mA

KSZ8895MQXIA

High-speed networking switch

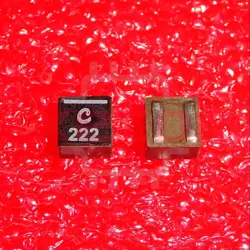

XGL4030-222MEC

2.2uH ±20% 7A 1616 Power Inductors ROHS

0900LP15B0063E

Ceramic Filters Low Pass 900MHz 0.9dB 50Ohm SMD 8Pin T/R

ZXMN10B08E6TA

ZXMN10B08E6TA is a N Channel MOSFET, featuring a voltage rating of 100V and a maximum current of 1.6A, with a low on-resistance of 230mΩ at 10V

ZXMN6A07FTA

Small Signal Field-Effect Transistor

MLX90614ESF-DCI-000-TU

Digital Temperature Sensor MLX90614ESF-DCI-000-TU, Operating Range: -40°C to 85°C, TO39 Enclosure

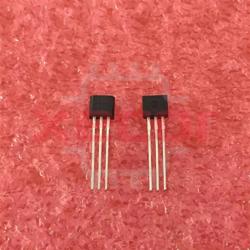

ZVN2106A

channel MOSFET with a voltage rating of 60V, current rating of 0.45A, and power dissipation of 0.7W, packaged in TO92

READ ALSO

-

How IoT solutions can help OEMs reduce costs in the aerospace industry Date: 04/10/2023

The potential of the Internet of Things in the aviation industry is endless. By effectively leveraging IoT, the aviation industry can focus on improving passenger safety, cost reduction, system maintenance, efficiency, safety, and customer experience.

-

How IoT is changing the healthcare industry Date: 04/10/2023

The adoption of the Internet of Things (IoT) has revolutionized the way the healthcare industry now works, as it has huge potential and multiple applications, from remote monitoring to medical device integration. In healthcare, IoT is used for interconnected medical devices like monitoring systems, sensor machines, and detectors that capture real-time health information and store it on centralized cloud/servers for later analysis to obtain Better healthcare services. All the big players in the i

-

IoT application processor chips and camera chips Date: 04/10/2023

In recent years, artificial intelligence technology and Internet of Things technology have gradually integrated and developed. Massive data is generated and collected through the Internet of Things and stored in device terminals, edges, and clouds. The data is then intelligently analyzed through machine learning, ultimately realizing the intelligent connection of all things data action, AIoT emerged as the times required. As the core component of AIoT equipment, the importance of chips has becom