Solenoid Switches: Function, Working principle, Transmission, Problems

The solenoid switch stands as a critical component in electrical systems, offering precise control over circuits and mechanisms. Understanding its function, working principle, role in transmission systems, and common problems is essential for comprehending its significance across diverse applications. From motor control to lighting systems, the solenoid switch plays a pivotal role in high-frequency switching applications. This article delves into the intricate details of the solenoid switch, shedding light on its fundamental operation and addressing potential challenges that may arise.

What is a Solenoid Switch

A solenoid switch, commonly known as a solenoid, serves as an electromechanical device adept at transforming electrical energy into mechanical motion. Its fundamental structure comprises essential components: a coil of wire, or solenoid, intricately wound around a cylindrical core, a movable plunger or rod, and a spring. The operation unfolds as the application of an electric current to the coil generates a magnetic field, compelling the plunger to move either towards or away from the core.

Delving into the intricate composition of a solenoid switch, key elements collaboratively contribute to its electromechanical prowess. The coil, meticulously fashioned from copper wire, stands as the primary component enveloping the solenoid's core. Upon the passage of an electric current, this coil initiates the generation of a magnetic field. The core, fashioned from ferromagnetic material, assumes a pivotal role in intensifying and concentrating this magnetic field. Its provision of a magnetic flux path significantly amplifies the solenoid's efficiency. The plunger, also known as the armature, emerges as a movable entity housed within the solenoid, typically crafted from ferrous material. The energization of the solenoid draws the plunger toward the core. Finally, a spring assumes a crucial role in orchestrating the plunger's return to its original position upon the discontinuation of the electrical current. This spring mechanism seamlessly guides the solenoid switch back to a default state when not actively engaged. The harmonized interplay among these components facilitates the versatile and dependable operation of solenoid switches across a spectrum of applications.

Specifications of Solenoid Switches

-

Fast Response: Solenoid switches can switch circuits within a few milliseconds, offering efficient and rapid switching capabilities.

-

Long Life: These switches have a lifespan of millions of on/off operations, significantly longer than conventional mechanical switches.

-

High Reliability: Solenoid switches are highly reliable, ensuring stable operation over long periods without failure. They are designed to withstand high currents and voltages, with contacts treated to resist arcing and abrasion, enhancing their durability.

-

Lightweight and Portable: Solenoid switches are small and lightweight, making them easy to install and transport. This feature is advantageous in space-constrained environments and facilitates easy repair and replacement.

-

Electromagnetic Operation: Solenoid switches operate through electromagnetism, powered by electricity.

-

Wide Voltage Range: They can function across a wide range of voltages, from low-voltage DC to high-voltage AC applications.

-

Compact Size: Solenoid switches are typically small, making them suitable for applications with limited space.

-

Quick Response Time: They offer fast on/off switching, ideal for applications requiring rapid response times.

-

Low Power Consumption: Solenoid switches are energy-efficient, consuming minimal power.

-

Weather Resistant: Many solenoid switches are designed to withstand various weather conditions, making them suitable for outdoor use.

-

Customizable: These switches can be customized to meet specific application needs, including mounting options, contact configuration, and voltage range.

What is the Function of a Solenoid Switch

The primary role of a solenoid switch is to trigger a robust switch, creating a link between the car's battery and the starter motor. Specifically, when the ignition key is rotated to the Start position, the solenoid switch becomes active, initiating the connection with the starter's drive pinion. This interaction enables the flow of electrical current from the battery to the starter motor, kickstarting the cranking process that sets the vehicle's engine in motion. Essentially, the solenoid switch acts as a pivotal intermediary device, ensuring the systematic and timely activation of the starter motor in direct response to the driver's ignition command.

The function of a solenoid switch encompasses various aspects related to circuit control, overload protection, safe power-off, and automation systems.

-

Circuit Control

A solenoid switch is integral to circuit control, serving as a mechanism to open or close electrical circuits. It can be controlled remotely, either manually or through automated systems, allowing for precise management of electrical currents within a circuit. This function is crucial in applications where controlled circuit activation or deactivation is required.

-

Overload Protection

Solenoid switches can be employed as part of overload protection systems. In the event of excessive current flowing through a circuit, the solenoid switch can be designed to respond by opening the circuit, preventing damage to components and ensuring the safety of the overall system. This protective function is especially critical in scenarios where electrical equipment might be subjected to unforeseen overloads.

-

Safe Power-Off

Solenoid switches contribute to safe power-off procedures. By utilizing the switch to interrupt the power supply, it ensures a secure and controlled shutdown of electrical systems. This is essential in situations where immediate power cessation is necessary for safety reasons or to prevent damage to sensitive equipment.

-

Automation System

Solenoid switches play a key role in automation systems. They can be integrated into automated processes to control the flow of electricity based on programmed or sensor-triggered conditions. This automation capability is employed in various industries, including manufacturing, where precise control over electrical circuits is needed for seamless and efficient operations.

How Does a Solenoid Switch Work

A solenoid switch operates by leveraging the principles of electromagnetism. It consists of a coil of wire, typically wound around a movable core known as an armature. The fundamental working mechanism involves the generation of an electromagnetic field when an electric current flows through the coil.

Electric Current Flow: When an electric current is applied to the coil, it creates a magnetic field around the coil due to the flow of electrons through the wire.

Electromagnetic Field Generation: The coil's electromagnetic field induces magnetism in the armature, the movable core within the solenoid.

Armature Movement: The armature is attracted or repelled by the magnetic field, depending on the direction of the current. This electromagnetic force compels the armature to move either towards or away from the coil.

Mechanical Action: The motion of the armature is harnessed to perform a mechanical action. In the context of a solenoid switch, this action typically involves opening or closing valves, switches, or other mechanical elements.

Conversion of Energy: The solenoid effectively transforms electrical energy into mechanical motion and force. This conversion is essential for various applications where controlled movement or switching is required.

In the case of a solenoid switch, the movement of the armature is designed to open or close the switch contacts, allowing or interrupting the flow of electrical current. This controlled switching action is utilized in a variety of devices and systems, ranging from automotive starters to industrial control systems.

In summary, a solenoid switch harnesses the electromagnetic forces generated by the flow of electric current through a coil to move a core (armature), thereby enabling mechanical actions such as opening or closing switches. This electromechanical functionality makes solenoid switches versatile components in numerous applications across different industries.

Types of Solenoid Switch

circuits. These switches typically have a single switched pole, and some, like starter solenoids in cars, are designed for momentary operation. When a car's engine is started, both the engine starter and the switch disconnect from the electrical system. In automotive systems, a moving plunger is used to slide the starter pinion with the starter shaft, connecting the flywheel to the starter motor and providing power.

There are several types of solenoids available, each with its own design and features:

-

AC Laminated Solenoid

-

DC C-Frame Solenoid

-

DC D-Frame Solenoid

-

Linear Solenoid

-

Rotary Solenoid

Solenoid valves, used to control fluid flow in tubes or conduits, employ different mechanisms to control the media. These valves come in various types, each with its own operating mechanism:

-

Direct Acting Solenoid Valve: These valves operate by using a plunger to directly close a small orifice without relying on external force. They are fast-acting and can operate at various pressures.

-

Pilot-Operated Solenoid Valve: Also known as an indirect-operated valve, it uses pressure difference to open or close the orifice between the valve ports. This type is more complex than direct-acting valves and requires less current to operate due to pressure amplification.

-

Two-Way Solenoid Valves: These valves have two ports to open or close fluid flow. They can be normally open (NO) or normally closed (NC) depending on whether the orifice allows flow when the coil is de-energized or energized.

-

Three-Way Solenoid Valve: These valves have three ports and two separate orifices, opening alternately based on the condition of the solenoid coil. They are commonly used to combine or separate two fluids.

-

Four-Way Solenoid Valve: These valves have four ports, two for pressure inlets and two for exhaust outlets. They are often used to control double-acting solenoid valve actuators, supplying incoming pressures and exhausting pressure openings.

Each type of solenoid valve has its own set of advantages and disadvantages, making them suitable for various applications in industrial, commercial, and household settings.

How to Check/Test a Solenoid Switch

Applications of Solenoid Switches

Solenoid switches find diverse applications across various industries due to their ability to control electrical circuits.

Motor Control:

Solenoid switches are extensively used in motor control applications. They play a crucial role in starting and stopping electric motors by controlling the flow of electrical currents. This is prevalent in industrial machinery, automotive systems, and other applications where precise motor control is essential.

Lighting Control:

Solenoid switches are employed in lighting control systems to regulate the on/off functionality of lights. They provide a reliable and efficient means to control the electrical circuit powering lighting fixtures in residential, commercial, and industrial settings.

Air-Conditioning Control:

Solenoid switches contribute to the control of air-conditioning systems. They are integrated into the circuitry to manage the operation of components such as compressors, fans, or dampers. Solenoid switches help regulate the flow of electrical currents to achieve desired temperature and ventilation control.

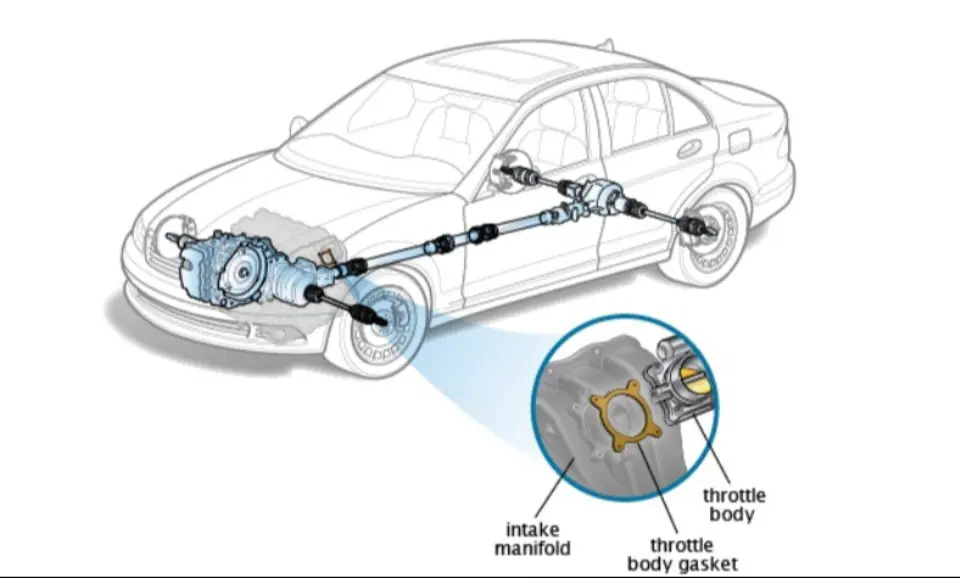

Automotive Applications:

In the automotive industry, solenoid switches are widely used for various functions. They are integral components in starter systems, fuel injectors, transmission control systems, and other critical components that require precise electrical control.

Industrial Automation:

Solenoid switches play a key role in industrial automation by controlling the operation of different devices and components in manufacturing processes. They are used to actuate valves, engage clutches, or control the movement of mechanical parts.

Security Systems:

Solenoid switches are utilized in security systems, such as electronic locks and access control systems. They contribute to the controlled locking and unlocking mechanisms in response to electronic signals or keycard inputs.

Medical Equipment:

In medical equipment, solenoid switches are employed for various purposes, including controlling the movement of robotic arms, adjusting positions in imaging devices, or managing fluid flow in medical instruments.

Appliance Control:

Solenoid switches are integrated into household appliances for controlling specific functions. They are used in washing machines, dishwashers, and other appliances to regulate water flow, door locks, or other operational aspects.

These applications highlight the versatility of solenoid switches in providing reliable and precise control over electrical circuits, making them integral components in a wide range of devices and systems.

Role of Solenoid Switch

Circuit Control:

Solenoid switches are utilized in controlling various circuits, including those in home electrical equipment, industrial automation systems, and power distribution systems. Activation of the solenoid coil allows the contacts to open or close the circuit through attraction or separation, thus enabling control of electrical equipment.

Overload Protection:

Solenoid switches can also serve as overload protection devices to safeguard electrical equipment from the risks of overload operation. When the circuit's current exceeds the rated value, the solenoid switch promptly interrupts the circuit to prevent equipment damage, fires, and other hazardous situations.

Safe Power-Off:

Solenoid switches are crucial for safe power-off procedures. In emergency scenarios such as equipment failure or accidents, it is essential to immediately cut off the power supply to ensure the safety of personnel and equipment. Solenoid switches can swiftly interrupt the circuit by controlling the electromagnetic coil, thus facilitating safe power-off and preventing further damage.

Automation Systems:

Solenoid switches play a vital role in automation systems, where they are used to control the operation of various electrical equipment and mechanical devices. When combined with sensors, actuators, and controllers, solenoid switches enable the execution of complex automated operations, thereby enhancing productivity and efficiency.

Automobile:

-

Solenoids carry a current that, when energized, creates a magnetic field. This magnetic field produces a high force and current source of power for activating devices used in electrical applications and vehicles, such as automotive and industrial equipment.

-

The solenoid switch triggers a durable switch that connects the vehicle's battery to the starter motor.

-

When the ignition key is in the initial position, this switch connects the drive pinion of the starter.

How to Fix/Repair a Solenoid Switch

Advantages of Solenoid Switches

The advantages of solenoid switches make them highly desirable for various applications.

Fast Switching and Long Life:

Solenoid switches excel in high-efficiency, high-frequency switching applications. Their design allows for fast and reliable switching, making them suitable for applications where quick response times are crucial. Additionally, solenoid switches typically have a long operational life, contributing to durability and sustained performance.

Dustproof, Waterproof, and Explosion-Proof:

Solenoid switches are designed to withstand challenging environmental conditions. They are often built to be dustproof and waterproof, ensuring reliable operation even in dusty or wet environments. Additionally, certain solenoid switches are engineered to be explosion-proof, making them suitable for use in hazardous locations where the risk of explosive atmospheres exists.

Compact and Lightweight:

Solenoid switches are characterized by their small size and lightweight construction. This compact design facilitates easy installation and maintenance in various applications. The reduced size and weight make solenoid switches particularly advantageous in situations where space is limited or weight considerations are crucial.

Energy Efficiency:

Solenoid switches are known for their energy-efficient operation. They consume minimal power during both the energized and de-energized states, contributing to overall energy efficiency in electrical systems. This makes them suitable for battery-operated or energy-conscious applications.

Versatility and Precision:

Solenoid switches offer versatility in their applications, providing precise control over electrical circuits. Their ability to control the movement of mechanical components or the flow of fluids makes them adaptable to a wide range of systems, from automotive applications to industrial automation.

Reliable Control Mechanism:

Solenoid switches provide a reliable control mechanism due to their simple yet effective design. The electromagnetic principle behind solenoid operation ensures consistent and repeatable performance, contributing to the overall reliability of systems in which they are employed.

How to Install/Replace a Solenoid Switch

Where is the Solenoid Switch Located

The solenoid switch in a vehicle holds a critical position within the starting system, typically found between the ignition module and the engine. It is commonly situated on or near the starter motor, playing a pivotal role in the initiation of the engine's cranking process. Often referred to as a starter solenoid or starter relay, this component operates electromagnetically. When the ignition key is turned, the solenoid switch receives both a substantial electrical current from the vehicle's battery and smaller electrical currents from the ignition system.

Functionally, the solenoid switch serves as a relay, facilitating the controlled transmission of electrical currents necessary for starting the engine. As it engages, the solenoid switch allows a large current to flow from the battery to the starter motor, activating the cranking process. This electromechanical operation ensures that the vehicle's engine starts reliably and efficiently in response to the driver's ignition command.

The strategic positioning of the solenoid switch between the ignition module and the engine underscores its significance in the starting sequence. Its location near the starter motor enables seamless coordination between the ignition system and the high-current demands of the starter motor, contributing to the overall reliability and functionality of the vehicle's starting system. In essence, the solenoid switch's role as an intermediary device ensures the orchestrated flow of electrical currents, translating the turn of the ignition key into the dynamic initiation of the engine.

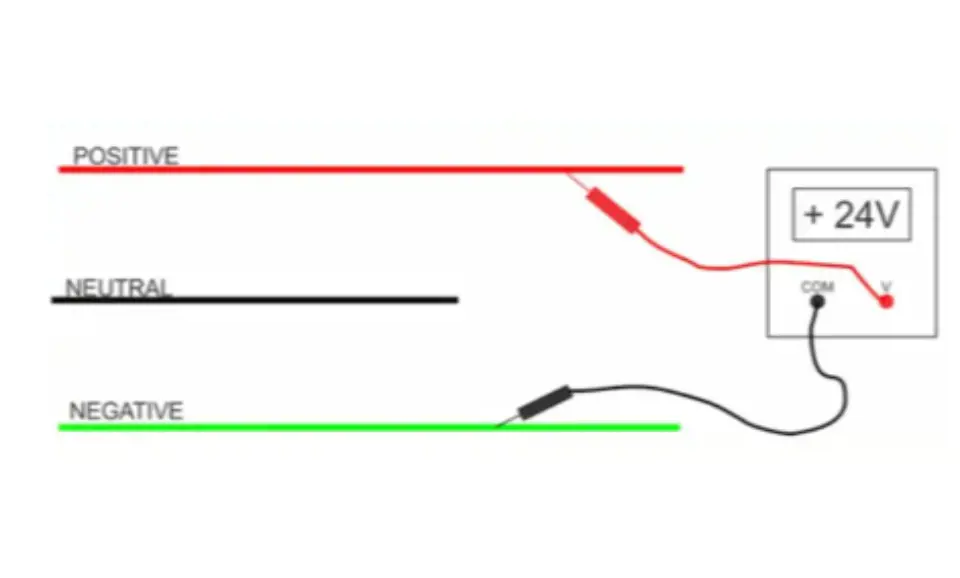

How to Wire a Solenoid Switch

These switches are primarily used to control circuits with high currents using a switch that requires low current.

These devices incorporate a switch with a high current rating, which is controlled by a magnetic actuator called a solenoid. When a small current flows through the solenoid, its core moves to force the high-current switch into the closed position. Depending on the size of the solenoid, it typically has four terminals. Two of these terminals are used for low-current circuits, while the remaining terminals are for the high-current circuit of the solenoid. Connecting a solenoid switch involves several steps:

-

Connect the high-current switch terminals to the solenoid switch, following the documentation provided with the switch for the position of the two terminals.

-

Cut two pieces of black wire. Connect one end of the first black wire to the negative terminal of the battery. Similarly, connect the second end of the wire to one of the high-current terminals of the switch.

-

Connect the other black wire to the remaining high-current terminal of the switch. Then, attach the other end of that wire to the DC motor's negative terminal.

-

Cut a piece of red wire and connect one end to the positive terminal of the motor, and attach the other end to the positive terminal of the battery, completing a high-current circuit.

-

Cut two pieces of black wire and connect one end of the first wire to the first low-current terminal on the switch. Attach the other end to one of the terminals of the 6V switch, and connect the remaining terminal to the negative terminal of the 6V battery.

-

Run a red wire from the positive terminal of the battery and connect the other end to the second low-current terminal on the switch, completing a low-current circuit.

-

Finally, turn ON the 6V switch, and the DC motor will start running.

Bad Solenoid Switch Symptoms and Problems

Indeed, a malfunctioning starter solenoid can manifest in several symptoms and problems, indicating potential issues in the starting system of a vehicle.

-

Engine Won't Start

One of the most apparent symptoms of a faulty starter solenoid is an engine that refuses to start. When the solenoid fails to engage and transmit the necessary electrical current to the starter motor, the engine won't initiate the cranking process.

-

Absence of Clicking Noise:

Typically, when you turn the ignition key to start the engine, a distinct clicking noise should be audible as the solenoid engages. If there is an absence of this clicking noise, it could indicate a problem with the solenoid not activating or transmitting power.

-

Spinning Starter Without Engaged Flywheel

Another potential sign is a spinning starter motor without successfully engaging the flywheel. A malfunctioning solenoid may fail to extend the starter drive pinion to mesh with the flywheel teeth, resulting in the starter motor spinning freely without cranking the engine.

-

Slow-Cranking Engine

A sluggish or slow-cranking engine can also be attributed to a bad solenoid. If the solenoid is not delivering sufficient electrical current to the starter motor, the engine may crank at a noticeably slower pace than usual, indicating an underlying issue.

Final Words

Solenoid switch emerges as a versatile and efficient player in the realm of electrical control. Its fast switching capabilities and long life make it indispensable for applications demanding high efficiency and reliability. The solenoid switch's compact design, coupled with its resistance to environmental extremes, enhances its suitability for various industries. As we navigate through the intricacies of its working principle and transmission applications, it becomes evident that the solenoid switch is not merely a component but a linchpin, seamlessly integrating into systems that power our daily lives.

Read More

FAQ

-

How much does it cost to replace a solenoid switch?

The cost of replacing a solenoid switch can vary based on factors such as the type of solenoid, the specific vehicle make and model, and whether it's a single solenoid or a solenoid pack.

The cost for a single transmission shift solenoid can range from $15 to $100.

A solenoid pack, which includes all the solenoids for a particular vehicle or transmission, can cost from $65 to several hundred dollars or more.

Labor costs for installation may also contribute to the overall expense. Labor charges vary depending on the location, the complexity of the job, and whether the solenoid replacement is part of a larger repair or maintenance service.

-

What happens when the solenoid goes bad?

Issues with the solenoid can trigger your vehicle to enter "limp mode," a safety mode designed to protect your engine and transmission from severe damage and potential accidents. In this mode, the vehicle's power and acceleration capabilities are significantly reduced.

-

What is the difference between a solenoid and a relay switch?

The distinction between a relay and a solenoid lies in their functions: a solenoid is utilized to trigger an action, whereas a relay is used to transfer current.

-

How does a solenoid switch work?

A solenoid operates by generating an electromagnetic field around a movable core, known as an armature. This armature is compelled to move by the electromagnetic field, causing it to open and close valves or switches, thereby converting electrical energy into mechanical motion and force.

-

What is a solenoid switch used for?

A solenoid switch is an electrical switch commonly used to activate high-current circuits, such as starter motor circuits, using a low-current switch.

-

What is the function of solenoid switch?

The solenoid switch is used to activate a heavy-duty switch that connects the vehicle's battery to the starter motor. When the ignition key is turned to the Start position, the solenoid switch engages the starter's drive pinion.

Dr. Benjamin Foster

Dr. Benjamin Foster

Still, need help? Contact Us: [email protected]